Oil-immersed distribution transformers Manufacturer-30kV 33kV 35kV 36.5kV 38kV

Key attributes

| Brand | Vziman |

| Model NO. | Oil-immersed distribution transformers Manufacturer-30kV 33kV 35kV 36.5kV 38kV |

| Rated voltage | 35kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 630kVA |

| Series | S11 |

Product descriptions from the supplier

Description

38kV oil-immersed distribution transformers Product Features

The 38.5kV oil-immersed distribution transformers produced by our company adopt a new type of insulation structure for the transformer body, which improves short-circuit resistance; the iron core is made of high-quality cold-rolled silicon steel sheets; the high-voltage windings are all made of high-quality oxygen-free copper wires and adopt a multi-layer cylindrical structure; all fasteners are subjected to special anti-loosening treatment.

The product features high efficiency and low loss, which can save a large amount of electricity consumption and operating costs with significant social benefits, making it a new technology product to be promoted.

38kV oil-immersed distribution transformers Reliable Structure

On the basis of traditional structures and mature technologies, our company has made many improvements, such as adopting:

-

Spiral windings with longitudinal oil ducts for better internal heat dissipation;

-

Improved effective support for the winding end faces, resulting in stronger short-circuit current resistance;

-

New hoisting structure and transformer body positioning structure to ensure higher reliability during long-distance transportation and operation;

-

We also have many unique and reliable structures to serve you;

-

Selecting transformers with higher performance levels will have a higher level of technological content.

38kV oil-immersed distribution transformers Technical parameters

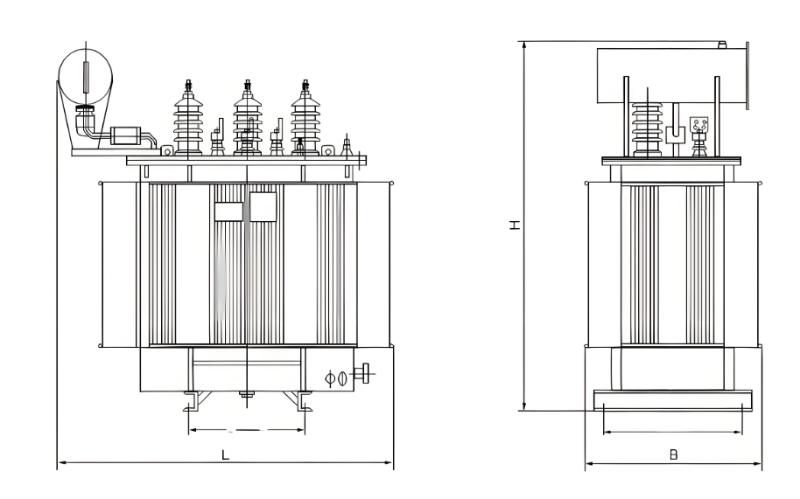

| Rated Capacity (kvar) | Voltage Combination & Tap Range (kV) | Connection Group Designation | No-Load Loss (W) | Load Loss (W) | No-Load Current (%) | Short-Circuit Impedance (%) | Body Lifting Weight | Oil Weight | Total Weight | Overall Dimensions (mm) (Length L × Width B × Height H) | Installation Dimensions | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High Voltage (kV) | High Voltage Tap Range (%) | Low Voltage (kV) |

|||||||||||

| 50 | 30, 33, 35, 36.5, 38 | ±5 | 0.4 | Yyn0 / Dyn11 | 160 | 1200/1140 | 1.3 | 360 | 200 | 650 | 1050×930×1400 | 550/550 | |

| 100 | 230 | 2010/1910 | 1.1 | 460 | 220 | 790 | 1050×940×1460 | 550/550 | |||||

| 125 | 270 | 2370/2260 | 1.1 | 490 | 240 | 850 | 1050×960×1510 | 550/550 | |||||

| 160 | 280 | 2820/2680 | 1 | 570 | 260 | 970 | 1050×980×1540 | 550/550 | |||||

| 200 | 340 | 3320/3160 | 1 | 670 | 300 | 1120 | 1100×1070×1600 | 550/550 | |||||

| 250 | 400 | 3950/3760 | 0.95 | 740 | 330 | 1260 | 1120×1100×1660 | 660/660 | |||||

| 315 | 480 | 4750/4530 | 0.95 | 890 | 360 | 1470 | 1130×1130×1710 | 660/660 | |||||

| 400 | 580 | 5740/5470 | 0.85 | 6.5 | 1020 | 400 | 1660 | 1750×850×1720 | 660/660 | ||||

| 500 | 680 | 6910/6580 | 0.85 | 1150 | 440 | 1870 | 1850×900×1760 | 660/660 | |||||

| 630 | 830 | 7860 | 0.65 | 1300 | 520 | 2180 | 1950×1000×1800 | 820/820 | |||||

| 800 | 980 | 9400 | 0.65 | 1510 | 560 | 2490 | 2060×1100×1990 | 820/820 | |||||

| 1000 | 1150 | 11500 | 0.65 | 1750 | 620 | 2880 | 2180×1200×1940 | 820/820 | |||||

| 1250 | 1400 | 13900 | 0.6 | 1940 | 670 | 3320 | 2200×1200×2000 | 820/820 | |||||

| 1600 | 1690 | 16600 | 0.6 | 2180 | 790 | 3870 | 2350×1330×2200 | 820/820 | |||||

| 2000 | 1990 | 19700 | 0.55 | 2450 | 820 | 4170 | 2080×1900×2250 | 1070/1070 | |||||

| 2500 | 2360 | 23200 | 0.55 | 2820 | 920 | 4860 | 2100×2180×2350 | 1070/1070 | |||||

38kV oil-immersed distribution transformers High-Quality Materials

Oxygen-free copper wires with lower resistivity are selected and undergo a series of additional surface treatments to be smoother without burrs or sharp corners, resulting in lower load loss and more reliable electrical performance of the transformer.

High-quality silicon steel sheets are selected. With the improvement of performance levels, silicon steel sheets with lower unit loss are adopted to reduce the no-load loss of the transformer.

High-quality laminated wood insulation parts are selected, which will never crack and remain motionless even under the action of short-circuit current.

Transformer oil that has undergone deep filtration is selected, with lower water, gas and impurity content, making the transformer work more reliably.

High-quality rubber sealing materials are selected to effectively prevent aging and eliminate leakage.

All raw materials have passed quality inspections. All raw material manufacturers have undergone strict reviews in accordance with the national standard ISO9000.

38kV oil-immersed distribution transformers Good Technical and Economic Performance

Compared with the S9 series, the S11 series products have an average reduction of 30% in no-load loss; the no-load current is 70-85% lower than that of the S9 series; the average temperature rise is reduced by 10K, the service life of the product is more than doubled, and it can still operate continuously even under the condition of 20% overload; the operating noise of the product is reduced by an average of 2-4 decibels.

38kV oil-immersed distribution transformers Fully Sealed

In S11(M)R, the letter "M" indicates that the oil tank adopts a fully sealed structure. Compared with ordinary oil-immersed transformers, the fully sealed distribution transformer cancels the oil conservator. The corrugated fins of the oil tank replace the oil pipes as cooling and heat dissipation elements. The corrugated oil tank is manufactured from high-quality cold-rolled thin plates on a special production line. The corrugated fins can expand and contract with the volume change of the transformer oil, thereby isolating the transformer from the atmosphere, preventing and slowing down oil deterioration and insulation moisture, enhancing operational reliability, and requiring no maintenance during normal operation.

The surface of the corrugated oil tank is degreased, derusted, phosphated and coated with three-proof paint, which is suitable for use in environments such as metallurgy, petrochemical and mining industries.

Documentation Resource Library

FAQ

Restricted.

Vziman IEC/ ANSI Oil-immersed Power transformer selection catalog

Catalogue

English

Consulting

Q: What maintenance is required for oil-immersed distribution transformers during operation?

A:

Daily checks include oil level, temperature and leakage. Monthly tasks involve cleaning bushing dust. Every 6-12 months, conduct oil sampling tests and calibrate accessories like gas relays. Every 3-5 years, perform insulation resistance and winding resistance tests to ensure reliability.

Q: What advantages do your oil-immersed distribution transformers have for industrial applications?

A:

Our units feature low loss (energy-saving), high short-circuit resistance, full-sealed oil tanks (anti-leakage/aging), and compliance with IEC/GB standards—ideal for industrial parks, mines, and infrastructure with harsh operating conditions.