Three Phase Oil Immersed On-Load Tap-Changing Power Transformers 35kV 38.5kV

| Brand | Vziman |

| Model NO. | Three Phase Oil Immersed On-Load Tap-Changing Power Transformers 35kV 38.5kV |

| Rated capacity | 1600kVA |

| No-load loss | 1.7W |

| Series | SZ-11 |

Oil Immersed On-Load Power Transformers Product Overview

- Installation Type: Outdoor

- Ambient Temperature: Maximum +40°C, Minimum –25°C

- Altitude: Up to 1,000 m above sea level

- Relative Humidity: ≤90% at +25°C

- Installation Environment: Free from corrosive gases and heavy pollution

- Primary Applications: Industrial power systems and transmission & distribution projects

Oil Immersed On-Load Power Transformers Structural Features

- The SZ11 Oil Immersed on-load tap-changing power transformer is a newly developed product designed in response to market demands, with reliability as the top priority. It features low losses, excellent performance, reliable operation, and stable output voltage, making it especially suitable for areas or applications where grid voltage fluctuates significantly.

- Three-Phase Oil Immersed On-Load Power Transformers feature reliable on-load voltage regulation capability, which can adjust the tap position smoothly without interrupting power supply, effectively stabilizing the output voltage and adapting to the fluctuation of grid load.

- Three-Phase Oil Immersed On-Load Power Transformers have strong environmental adaptability, and their sealed oil tank structure can resist the erosion of harsh environments such as humidity, dust and salt mist, making them suitable for various application scenarios including industrial parks, mining areas and coastal power grids.

Oil Immersed On-Load Power Transformers Compliance Standards

- GB 1094.1 & GB 1094.2–2013: Power Transformers

- GB 1094.3–2003 & GB 1094.5–2008: Power Transformers

- GB/T 6451–2015: Technical Parameters and Requirements for Oil-Immersed Power Transformers

- IEC 60076-2、IEC 60076-3、IEC 60076-5

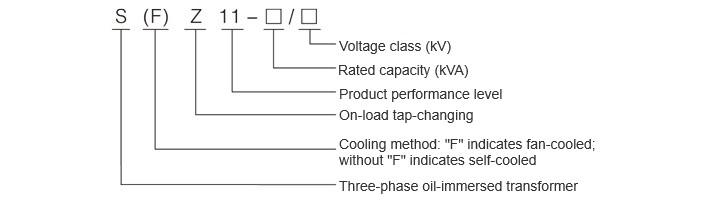

Oil Immersed On-Load Power Transformers Model Designation and Its Meaning

| Rated Capacity (kVA) | Voltage Combination | Connection Group Designation | No-Load Loss (W) | Load Loss (W) | Short-Circuit Impedance (%) | No-Load Current (%) | Weight (T) | |||

| High Voltage (kV) | Low Voltage (kV) | Oil Weight | Total Weight | Added Oil Weight | ||||||

| SZ11-1600/35 |

35 ± 3x2.5% 38.5± 3x2.5% |

11 10.5 6.6 6.3 |

Yd11 | 1.7 | 17.5 | 6.5 | 1.10 | 1.9 | 6.55 | 0.45 |

| SZ11-2000/35 | 2.2 | 19.2 | 6.5 | 1.00 | 2.14 | 7.4 | 0.56 | |||

| SZ11 -2500/35 | 2.55 | 20.6 | 6.5 | 1.00 | 2.3 | 8.5 | 0.63 | |||

| SZ11-3150/35 | 3.03 | 24.6 | 7.0 | 0.90 | 2.6 | 9.77 | 0.72 | |||

| SZ11-4000/35 | 3.63 | 29 | 7.0 | 0.90 | 2.85 | 11.97 | 0.78 | |||

| SZ11-5000/35 | 4.35 | 34 | 7.0 | 0.80 | 3.26 | 13.55 | 0.85 | |||

| SZ11 -6300/35 | 5.28 | 36.6 | 7.5 | 0.80 | 3.78 | 16.17 | 0.86 | |||

| SZ11-8000/35 |

35 ± 3x2.5% 38.5± 3x2.5% |

10.5 6.3 |

Ynd11 | 7.38 | 40 | 7.5 | 0.70 | 4.73 | 18.7 | 0.9 |

| SZ11-10000/35 | 8.7 | 47.8 | 7.5 | 0.70 | 4.83 | 20.3 | 1 | |||

| SZ11-12500/35 | 10.26 | 56.6 | 8.0 | 0.60 | 6.2 | 26.1 | 1.2 | |||

| SZ11-16000/35 | 12.2 | 59.1 | 8.0 | 0.60 | 8.3 | 34.2 | 2 | |||

| SZ11-20000/35 | 14.5 | 83.5 | 8.0 | 0.60 | 8.6 | 38.5 | 2.1 | |||

| SZ11-25000/35 | 17.1 | 98.8 | 8.0 | 0.55 | 8.9 | 42.3 | 2.2 | |||

| SZ11-31500/35 | 20.3 | 118.5 | 8.0 | 0.55 | 9.2 | 44.8 | 2.3 | |||

Three Phase Oil Immersed On-Load Power Transformers Operating Conditions

- Ambient Temperature Condition:Oil Immersed On-Load Power Transformers shall be used in an environment where the maximum ambient temperature does not exceed 40℃, and the minimum ambient temperature is not lower than -25℃. For areas with extreme low temperatures below -25℃, low-temperature resistant transformer oil should be configured to ensure the fluidity of the oil medium and the normal operation of Oil Immersed On-Load Power Transformers.

- Ambient Humidity Condition:Oil Immersed On-Load Power Transformers are suitable for environments with a relative humidity not exceeding 90% (at 25℃, no condensation). The fully sealed structure of Oil Immersed On-Load Power Transformers can effectively resist moisture erosion, making it applicable to humid scenarios such as coastal industrial zones and underground substations.

- Environmental Cleanliness Condition:Oil Immersed On-Load Power Transformers allow operation in environments with moderate dust, but it is strictly prohibited to use them in places with heavy dust accumulation, corrosive gases or flammable and explosive vapors. For dusty working conditions such as metallurgy and mining, simple dust-proof shielding measures should be taken for Oil Immersed On-Load Power Transformers to prevent dust from entering the internal components and affecting insulation performance.

- Power System Condition:Oil Immersed On-Load Power Transformers are applicable to AC 50Hz (or 60Hz according to customization) power systems, and the system voltage fluctuation shall not exceed ±5% of the rated voltage of the transformer. The on-load tap-changing function of Oil Immersed On-Load Power Transformers can only be activated under the condition of matching the system load, avoiding frequent tap switching that may cause mechanical wear of the equipment.

The on-load power transformers feature a robust tap-changer mechanism that physically switches between transformer winding taps while energized, adjusting the output voltage in real-time to compensate for load variations or grid fluctuations. While designed for durability with minimal maintenance, regular oil analysis and periodic inspection of the OLTC contacts are recommended as part of a preventive maintenance schedule to ensure long-term reliability and performance of the transformer.

Our on-load power transformers provide critical operational flexibility and enhanced power quality. They allow voltage regulation without interrupting the power supply, which is essential for maintaining grid stability, supporting sensitive industrial processes, and improving overall system efficiency. The oil-immersed design ensures effective cooling and insulation, making these 35kV/38.5kV units highly reliable for continuous, demanding operations.