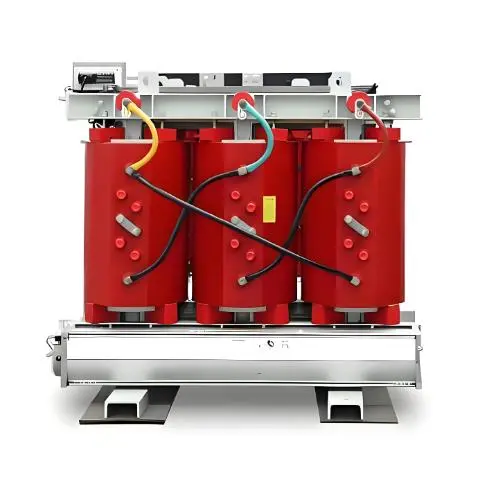

Epoxy-resin Dry-Type Distribution Transformer Manufacturers-22kV 35kV 38.5kV 44kV

| Brand | Vziman |

| Model NO. | Epoxy-resin Dry-Type Distribution Transformer Manufacturers-22kV 35kV 38.5kV 44kV |

| Rated voltage | 22kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 400kVA |

| Series | SCB |

- Insulation Structure: They utilize high-performance insulating materials to ensure safe and reliable operation in high-voltage environments, minimizing the risk of electrical leakage.

- Heat Dissipation: Designed with effective heat dissipation capabilities, they can efficiently release heat generated during operation, ensuring stability and reliability.

- Environmentally Friendly: These transformers do not use liquid insulating mediums, which eliminates the risk of oil leaks and environmental pollution, aligning with eco-friendly standards.

- Easy Maintenance: The dry-type design reduces the need for regular maintenance, lowering operational costs.

- Flexible Installation: With a smaller size and lighter weight, they allow for more flexible installation options, making them suitable for various applications.

- High Efficiency: Under normal operating conditions, they exhibit high energy conversion efficiency, contributing to reduced energy consumption.

- Wide Applicability: They are widely used in urban distribution systems, industrial power, building facilities, and renewable energy projects such as wind and solar.

Epoxy-Resin Dry-Type Distribution Transformer Technical Specification

Technical Data for 35kV Class Three Phase Epoxy-resin Dry-type Distribution Transformer

|

Rated Power

(KVA)

|

High Voltage

(KV)

|

Low Voltage

(KV)

|

Connection Symbol

|

On-load Loss

(W)

|

No-Load Current(%)

|

|

50

|

35

38.5

44

or others

|

0.4

|

Dyn11

YNyn0

|

1500

|

2.8

|

|

100

|

2200

|

2.4

|

|||

|

160

|

2960

|

1.8

|

|||

|

200

|

3500

|

1.8

|

|||

|

250

|

4000

|

1.6

|

|||

|

315

|

4750

|

1.6

|

|||

|

400

|

5700

|

1.4

|

|||

|

500

|

7000

|

1.2

|

|||

|

630

|

8100

|

1.2

|

|||

|

800

|

9600

|

1.2

|

|||

|

1000

|

11000

|

1.0

|

|||

|

1250

|

13400

|

0.9

|

|||

|

1600

|

16300

|

0.9

|

|||

|

2000

|

19200

|

0.9

|

|||

|

2500

|

23000

|

0.9

|

|||

|

5000

|

46000

|

0.8

|

Technical Data for 20kV Class Three Phase Epoxy-resin Dry-type Distribution Transformer

|

Rated Power

(KVA)

|

High Voltage

(KV)

|

Low Voltage

(KV)

|

Connection Symbol

|

On-load Loss

(W)

|

No-Load Current(%)

|

|

50

|

20

22

24

or others

|

0.4

|

Dyn11

YNyn0

|

1300

|

2.4

|

|

100

|

2100

|

2.2

|

|||

|

160

|

2600

|

1.8

|

|||

|

200

|

3100

|

1.8

|

|||

|

250

|

3600

|

1.6

|

|||

|

315

|

4300

|

1.6

|

|||

|

400

|

5100

|

1.4

|

|||

|

500

|

6100

|

1.4

|

|||

|

630

|

7200

|

1.2

|

|||

|

800

|

8700

|

1.2

|

|||

|

1000

|

10300

|

1.0

|

|||

|

1250

|

12150

|

0.9

|

|||

|

1600

|

14600

|

0.9

|

|||

|

2000

|

17250

|

0.8

|

|||

|

2500

|

20400

|

0.8

|

|||

|

5000

|

35800

|

0.7

|

Technical Data for 10kVClass Three Phase Epoxy-resin Dry-type Distribution Transformer

|

Rated Power

(KVA)

|

High Voltage

(KV)

|

Low Voltage

(KV)

|

Connection Symbol

|

On-load Loss

(W)

|

No-Load Current(%)

|

|

50

|

6

6.3

6.6

10

10.5

11

13.2

or others

|

0.4

|

Dyn11

YNyn0

|

990

|

2

|

|

100

|

1570

|

1.8

|

|||

|

160

|

2120

|

1.4

|

|||

|

200

|

2520

|

1.4

|

|||

|

250

|

2750

|

1.4

|

|||

|

315

|

3460

|

1.2

|

|||

|

400

|

3980

|

1.2

|

|||

|

500

|

4880

|

1.2

|

|||

|

630

|

5870

|

1

|

|||

|

800

|

6950

|

1

|

|||

|

1000

|

8120

|

0.8

|

|||

|

1250

|

9690

|

0.8

|

|||

|

1600

|

11730

|

0.8

|

|||

|

2000

|

14450

|

0.6

|

|||

|

2500

|

17170

|

0.6

|

|||

|

5000

|

34600

|

0.5

|

Our transformers utilize high-voltage epoxy resin vacuum casting technology, achieving a fully sealed structure with the following core advantages:

-

Absolute Safety: Oil-free design, flame-retardant and explosion-proof, suitable for densely populated areas

-

Strong Environmental Adaptability: Protection rating up to IP54, capable of stable operation in humid and contaminated environments

-

Cost-Effective and Efficient: No-load losses are 15%-20% lower than national standards, offering significant lifecycle cost advantages

This product is specifically optimized for the following scenarios:

-

New Energy Sector: Photovoltaic power station step-up systems, wind farm collection lines

-

Industrial Applications: Explosion-proof areas in chemical plants, steel mill rolling mill power supply

-

Infrastructure: Metro traction substations, data center UPS systems

-

Special Environments: Island substations, core distribution rooms in high-rise buildings