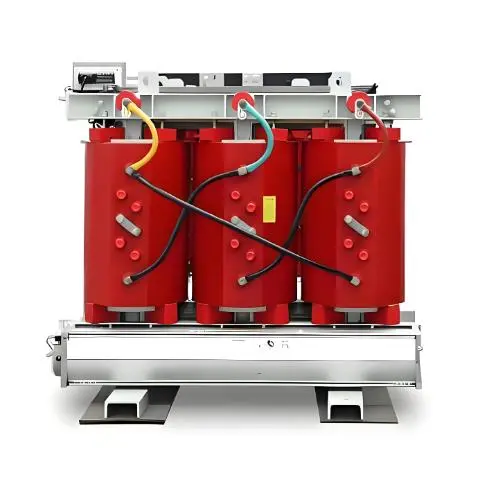

13.8kV 22kV Low Loss Noise Cast Resin Dry Type Distribution Transformer Copper Windings

Key attributes

| Brand | Vziman |

| Model NO. | 13.8kV 22kV Low Loss Noise Cast Resin Dry Type Distribution Transformer Copper Windings |

| Rated voltage | 22kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 250kVA |

| Series | SCB |

Product descriptions from the supplier

Description

Cast-Resin Distribution Transformer Introduction

The three-phase Cast-Resin Distribution Transformer is a high-performance Dry Type Distribution Transformer boasting core features including low loss, compact size, light weight, low noise, anti-clamping, anti-fouling, high mechanical strength, flame resistance, strong overload capacity, and low partial discharge. This Cast-Resin Distribution Transformer is widely applied in power transmission and distribution systems, hotels, restaurants, commercial buildings, stadiums, chemical plants, stations, airports, and offshore drilling platforms—especially suitable for heavy load centers and places with special fire protection requirements.

The SC(B) series products are epoxy-cast, no-load tap changer Dry Type Distribution Transformer equipped with vibration-damping devices to meet strict structural and low-noise requirements. As a premium Cast-Resin Distribution Transformer, it adopts F-class insulation, which is vacuum degassed before being injected into winding molds reinforced with glass fiber mesh. This process significantly improves the Dry Type Distribution Transformer’s mechanical strength, electrical strength, and heat resistance, endowing it with flame-retardant, explosion-proof, and pollution-free properties that address users’ core safety concerns.

The Cast-Resin Distribution Transformer is equipped with a monitoring system that controls the fan cooling system based on operating temperature and sends over-temperature trip signals in extreme conditions, ensuring safe operation. The Dry Type Distribution Transformer offers optional enclosures made of stainless steel, spray-coated cold-rolled steel, or aluminum alloy, with customizable inlet and outlet modes (top-in-top-out, bottom-in-top-out, bottom-in-bottom-out) to fit diverse installation needs. Compared to the SC(B)11 series, this Cast-Resin Distribution Transformer features enhanced energy efficiency, maintenance-free operation, and excellent moisture resistance, making it ideal for high-humidity and other harsh environments.

Cast-Resin Distribution Transformer Feature

- Flame-Retardant, Explosion-Proof & Pollution-Free:The Cast-Resin Distribution Transformer adopts epoxy resin casting technology, eliminating oil leakage risks. As an Dry Type Distribution Transformer, it is inherently flame-retardant, explosion-proof, and pollution-free, meeting strict safety standards for fire-sensitive sites.

- Strong Mechanical & Electrical Performance:This Dry Type Distribution Transformer has high short-circuit resistance and good lightning impulse resistance, thanks to its reinforced winding structure and high-quality insulation. The Cast-Resin Distribution Transformer’s robust design ensures stable operation under complex grid conditions.

- Low Maintenance & Energy-Saving:The Cast-Resin Distribution Transformer requires minimal maintenance due to its dry-type structure, reducing long-term operational costs. Its low-loss design delivers excellent energy-saving effects, outperforming traditional models in efficiency.

- Vibration-Damping & Low-Noise Design:Equipped with professional vibration-damping devices, the Dry Type Distribution Transformer operates with ultra-low noise, suitable for noise-sensitive environments. The Cast-Resin Distribution Transformer’s structural optimization further minimizes operational noise and vibration.

Cast-Resin Distribution Transformer Technical Parameters

| Capacity (KVA) | Voltage Combination | No-Load (W) | Under Different Insulation Heat-resisting Rank Load Loss (W) | No-Load Current (%) | Short Circuit Impedance (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| HV (kV) | HV (Tapping) | LV (kV) | 130℃(B) (100℃) | 155℃(F)

(120℃)

|

180℃(H)

(145℃)

|

||||

| 30 | 6 6.3 6.6 10 10.5 11 |

±5% ±2×2.5% |

0.4 | 130 | 605 | 640 | 685 | 2.00 | 4 |

| 50 | 185 | 845 | 900 | 965 | 2.00 | ||||

| 80 | 250 | 1160 | 1240 | 1330 | 1.50 | ||||

| 100 | 270 | 1330 | 1415 | 1520 | 1.50 | ||||

| 125 | 320 | 1565 | 1665 | 1780 | 1.30 | ||||

| 160 | 365 | 1800 | 1915 | 2050 | 1.30 | ||||

| 200 | 420 | 2135 | 2275 | 2440 | 1.10 | ||||

| 250 | 490 | 2330 | 2485 | 2665 | 1.10 | ||||

| 315 | 600 | 2945 | 3125 | 3355 | 1.00 | ||||

| 400 | 665 | 3375 | 3590 | 3850 | 1.00 | ||||

| 500 | 790 | 4130 | 4390 | 4705 | 1.00 | ||||

| 630 | 910 | 4975 | 5290 | 5660 | 0.85 | ||||

| 630 | 885 | 5050 | 5365 | 5760 | 0.85 | 6 | |||

| 800 | 1035 | 5995 | 6295 | 6715 | 0.85 | ||||

| 1000 | 1205 | 6885 | 7315 | 7885 | 0.85 | ||||

| 1250 | 1420 | 8190 | 8720 | 9335 | 0.85 | ||||

| 1600 | 1665 | 9945 | 10555 | 11320 | 0.70 | ||||

| 2000 | 2075 | 12240 | 13005 | 14005 | 0.70 | ||||

| 2500 | 2450 | 14535 | 15445 | 16605 | 0.70 | ||||

| Vector Group | Dyn11

|

||||||||

Cast-Resin Distribution Transformer Operating Conditions

- Ambient temperature: -25°C to +40°C

- Altitude: ≤1000m (customizable for higher altitude use for the Cast-Resin Distribution Transformer)

- Relative humidity: ≤95% (25°C, non-condensing)

- Applicable fire-sensitive sites: High-rises, hospitals, data centers, airports, subway stations

- Grid voltage fluctuation tolerance: ±5% (customizable to ±10% for the Dry Type Distribution Transformer)

Cast-Resin Distribution Transformer Application Scenarios

- Data Centers & Precision Electronics Facilities:Data centers demand stable, low-noise, and fire-safe power. The Cast-Resin Distribution Transformer’s low partial discharge and flame-retardant properties protect sensitive equipment, while the Dry Type Distribution Transformer’s moisture resistance adapts to high-humidity data center environments.

- Offshore Drilling Platforms:Offshore environments are harsh with high humidity, salt fog, and vibrations. The Dry Type Distribution Transformer’s corrosion-resistant enclosure and vibration-damping design withstands offshore conditions, and the Cast-Resin Distribution Transformer’s insulation resists salt fog erosion, ensuring reliable power for drilling equipment.

- Chemical Plants & Petrochemical Facilities:Chemical sites have strict anti-pollution and fire safety requirements. The Cast-Resin Distribution Transformer is pollution-free and flame-retardant, avoiding risks of chemical reactions with oil. The Dry Type Distribution Transformer’s anti-fouling insulation adapts to dusty, corrosive industrial environments.

Documentation Resource Library

FAQ

Restricted.

Vziman IEC/ ANSI Dry-Type Power transformer selection catalog

Catalogue

English

Consulting

Q: Why choose copper windings over aluminum in dry-type transformers?

A:

Copper windings offer higher conductivity, better thermal performance, and superior mechanical strength, ensuring lower losses, longer lifespan, and enhanced overload capacity in demanding applications.

Q: What are the main advantages of low-loss, low-noise epoxy cast dry-type transformers?

A:

They provide energy savings through reduced electrical losses, quiet operation suitable for noise-sensitive areas, and enhanced safety with fire-resistant, maintenance-free epoxy encapsulation. The use of full copper windings further improves efficiency and durability.