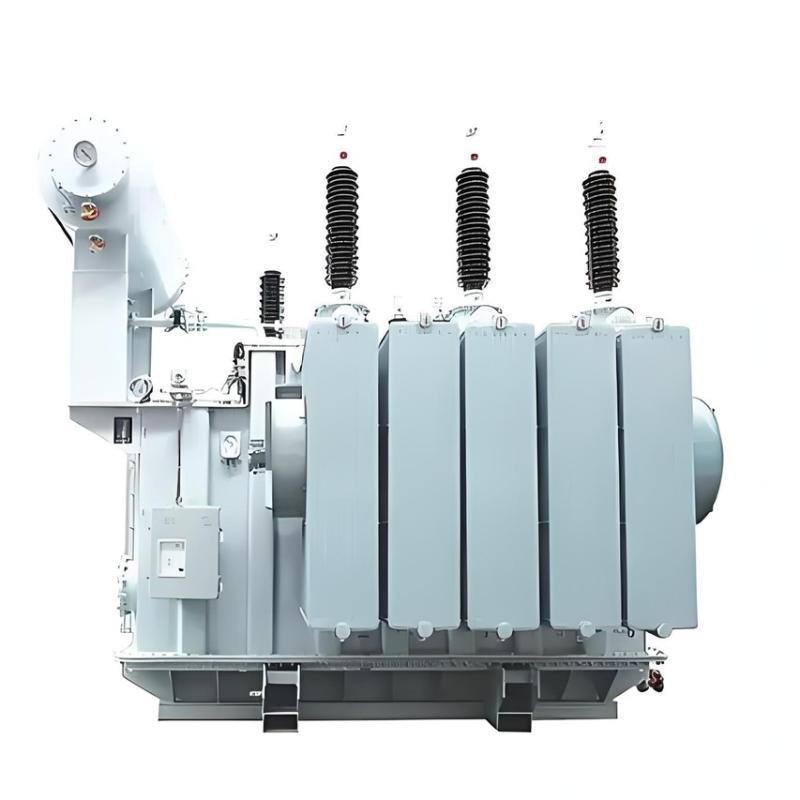

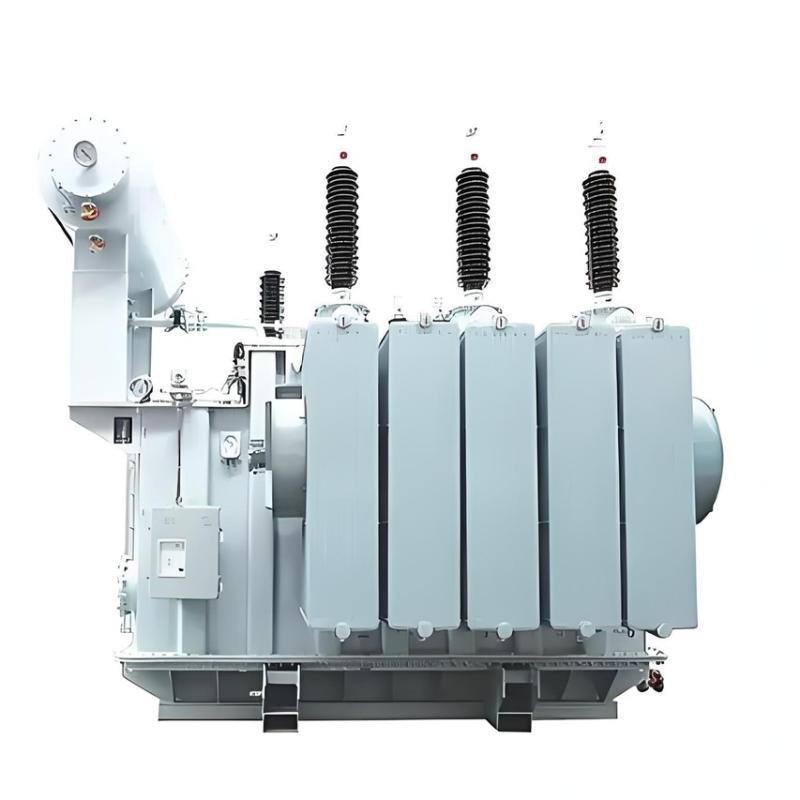

HV Oil-immersed Power Transformers-60kV 63kV 66kV 69kV

| Brand | Vziman |

| Series | S |

Leading HV oil-immersed power transformers manufacturer that has provided a total solution for power generation systems! There is nothing like Vziman Industrial Systems for HV Oil-Immersed Power Transformers

HV Oil-immersed Power Transformers Features

- Coils:There are different structures and methods of coil winding according to capacity, volume and its usage. Vziman has applied the optimal coil winding obtained through years of research and development. The size of the conductor has been designed to tolerate allowable currents, temperature increase, and the electromagnetic force that occurs in case of external short-circuit. The concentric arrangement that inserts primary and secondary coils based on the core is the standard method of arrangement with the insulation classification and mechanical force taken into account.

- Cores:The iron core is made of sophisticated highly permeable magnetic silicon steel laminated with no secular variations and is designed to minimize the vibration and noise during operation by minimizing no-load current and loss through precision cutting processes. The junction between Leg and Yoke Core has been manipulated through precision processing of 45℃ to take advantage of directivity of rolling and has also underwent the annealing process at 800℃ to eliminate magnetic properties.

- Tank:Being made of cold rolled steel, the tank is able to endure internal pressure, and it was also designed and manufactured with a harnessed mechanical force to prevent any deformation caused by external shocks while transportation or other factors.

- Conservator:The conservator and external cover of the HV oil-immersed power transformers are connected through a suitable pipe with an oil gauge attached to it. In addition, the conveyor and the case are detachable, if needed, as they are assembled by bolts.

HV Oil-immersed Power Transformers Specification

| Rating | Specification |

| Standard | IEC 60076 / ANSI(IEEE) C57 |

| Installation location | Outdoor/Indoor |

| Frequency | 50 / 60Hz |

| Thermal class | A type 105°C |

| Winding temp. rising | 65K |

| Oil Temp. rising | 60K |

| Cooling method Internal | ON / OF / OD |

| External | AN / AF / WF |

| Voltage | Up to 69kV |

| Capacity (MVA) | Up to 80MVA |

| Conductor | Al or Cu |

Yes, regular testing and replacement based on oil quality are required. An oil quality test (including dielectric loss, breakdown voltage, water content and other indicators) is usually conducted every 3–5 years. If the oil quality deteriorates or is severely contaminated, filtration, purification or full replacement must be carried out in a timely manner to ensure the insulation and heat dissipation performance meet the standards.

Q:What is the overload capacity of a HV oil-immersed transformers?

A:Under normal circumstances, it can withstand 1.1 times the rated load for long-term operation, and can bear 1.25–1.5 times the overload load for a short period (within 2 hours). The specific overload capacity shall be determined according to the transformer model, cooling method and ambient temperature. It is recommended to refer to the product technical parameter table.

Q:What are the advantages of HV oil-immersed transformers compared with dry-type transformers?

A:In high-voltage scenarios, oil-immersed transformers have higher heat dissipation efficiency and stronger overload capacity. Moreover, the arc-extinguishing characteristics of insulating oil can reduce the risk of internal faults, and the service life is longer (usually 5–10 years longer than dry-type transformers). They are more suitable for outdoor, heavy-load and high-voltage large-capacity scenarios.

Q:What optimizations has Vziman applied to the coils of HV oil-immersed power transformers?

A:Vziman adopts optimally designed coil winding structures developed through years of R&D. The conductor size is engineered to withstand allowable currents, temperature rises, and electromagnetic forces from external short circuits. Primary and secondary coils are concentrically arranged around the core, with insulation classification and mechanical strength fully considered.

Q:What materials and processes are used for the core of Vziman HV oil-immersed transformers?

A:The core is made of high-permeability magnetic silicon steel with no secular variations. Precision cutting minimizes no-load current and loss, reducing operational vibration and noise. Leg-yoke junctions undergo 45℃ precision processing (utilizing rolling directionality) and 800℃ annealing to eliminate magnetic properties.

Q:How is the tank of Vziman HV oil-immersed transformers designed for durability?

A:Constructed from cold-rolled steel, the tank resists internal pressure. It is engineered with enhanced mechanical strength to prevent deformation from external impacts during transportation or other scenarios.