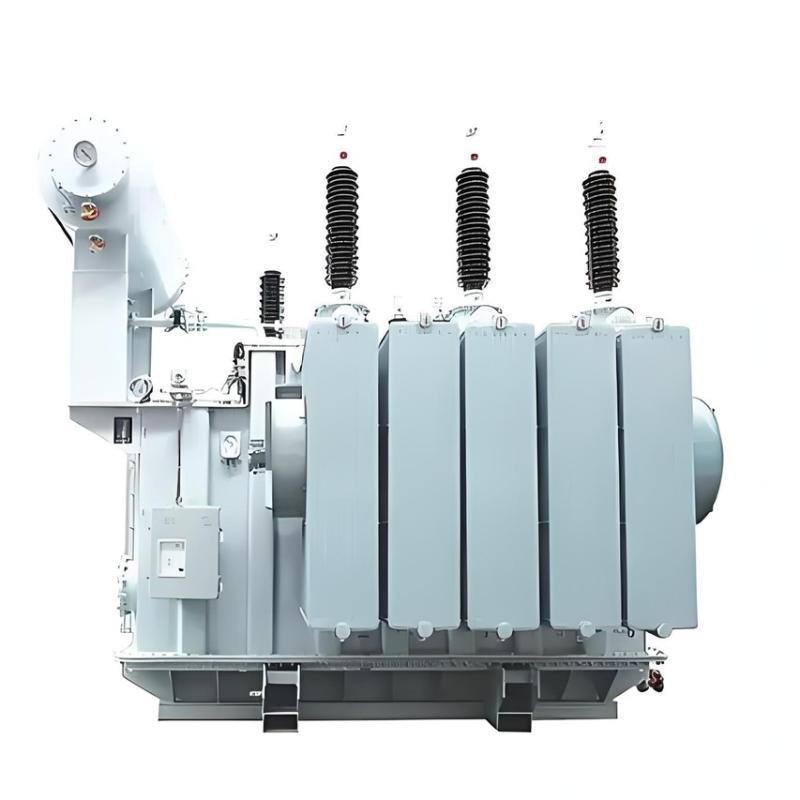

ONAN/ONAF Liquid-Immersed power Transformers-123kV 125kV 126kV 132kV 138kV 145kV

| Brand | Vziman |

| Model NO. | ONAN/ONAF Liquid-Immersed power Transformers-123kV 125kV 126kV 132kV 138kV 145kV |

| Rated voltage | 145kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 100kVA |

| Series | SG |

145kV Liquid-Immersed Power Transformers

Liquid-Immersed Power Transformers use insulating oil as both a cooling and insulating medium. They offer excellent heat dissipation, high-voltage endurance, strong overload capacity, and long service life. Their oil circulation cooling system is well-suited for high-capacity, heavy-load operation. Robust tank construction, combined with oil condition monitoring technologies—such as Buchholz relays and dissolved gas analysis (DGA)—ensures high operational reliability. Economical and practical, liquid-Immersed power transformers dominate applications in outdoor substations and renewable energy power stations. Enhanced safety features, including pressure relief valves and environmentally improved insulating oils, enable these transformers to strike an optimal balance among performance, cost, and maintenance convenience, making them the mainstream choice in medium- and high-voltage power systems.

145kV Liquid-Immersed Power Transformers Technical Features

High-permeability grain-oriented silicon steel cores and optimized winding designs significantly reduce no-load and load losses, achieving internationally leading energy efficiency standards.

Innovative low-noise cooling fans integrated with intelligent temperature control technology enhance thermal performance while ensuring quiet operation.

Electromagnetic-mechanical coupled simulation optimizes winding support structures; combined with high-strength insulation materials, this ensures safety and stability under grid fluctuations or fault conditions.

Key characteristics include low losses, low noise, low partial discharge, and low temperature rise.

145kV Liquid-Immersed Power Transformers Product Features

| Feature | Specification |

| Voltage Rating | 145 kV and below |

| Capacity | 100 MVA and below |

| Insulation Class | A/E/B Class |

| Application Environment | Widely used in industrial, agricultural, transportation, and urban community distribution systems. Suitable for indoor or outdoor installation, meeting various operational requirements of customers. |

145kV Liquid-Immersed Power Transformers Technical Specifications

| Parameter | Specification |

| Rated Capacity (kVA) | 3150–31500 |

| Voltage Ratio | 10/0.4 kV, 35/10 kV |

| Rated Frequency (Hz) | 50/60 |

| Number of Phases | 3 |

| High-Voltage Side Tap Range | ±2×2.5% |

| Voltage Regulation Method | No-Load Voltage Regulation |

| Cooling Type | ONAN/ONAF, KNAN/KNAF |

| Connection Group Designation | Dyn11 |

| Insulation Level (kV) | LI200AC85 / LI-AC10 |

| Insulation Heat Resistance Class | A, B, E |

| Temperature Rise Limit (K) | ≤60 |

| Top Oil Temperature Rise (Average) | ≤65 |

| No-Load Loss (kW) | GB 20052-2020 |

| Load Loss (kW) | IEC 60076-20-2017 |

| EU Standard | EU 548/2014 |

| Corrosion Protection Grade | C5 |

| Service Life | ≥25 years |

| Transformer Insulating Fluid | Ester-based insulating fluid: Midel 7131 or FR3 |

A liquid-immersed power transformers is a type of electrical transformer that uses oil as both a coolant and an insulator. This design helps keep the transformers cool and protects it from electrical faults. The oil circulates within the transformers, allowing it to handle heavy loads and operate efficiently over time.

Q:What are the benefits of using liquid-immersed power transformers?

A:Liquid-immersed power transformers have several benefits. They offer excellent cooling, which helps prevent overheating, and they are designed for heavy-load operations. Additionally, they have features like oil monitoring systems to ensure reliability. These transformers are also built to last, making them efficient and economical for power distribution.

Q:How long do liquid-immersed power transformers last?

A:Liquid-immersed power transformers typically have a long lifespan, often exceeding 25 years. This durability is due to their robust construction and the high-quality materials used in their manufacturing, which helps them withstand various environmental conditions.