Medium-Voltage Power Oil-Immersed Transformers: Structural Optimization, Lifecycle Economics, and Multi-Scenario Adaptability

1.Structural Principles and Efficiency Advantages

1.1 Structural Differences Affecting Efficiency

- Wound-core dry-type transformers feature a closed magnetic path with no joints, ensuring uniform flux distribution. This reduces high-order harmonics and associated losses.

- Field data shows that, for equivalent ratings (e.g., 2.5 MVA), wound-core dry-type transformers achieve 15%–30% lower no-load losses and 40% lower no-load currents compared to conventional laminated-core oil-immersed units, along with noise levels below 55 dB(A)—ideal for noise-sensitive environments.

1.2 Operating Principles Minimizing Losses

- Foil-wound low-voltage windings that suppress eddy current losses;

- Magnetic and electrostatic shielding to attenuate stray losses caused by 3rd/5th harmonic currents;

- Lower secondary-side currents at MV levels inherently reduce I²R conduction losses in downstream circuits compared to low-voltage systems.

1.3 Supply Architecture Optimizing System Losses

MV transformers enable a modern distribution strategy: “deep penetration into load centers with dense substation placement.” By siting 10/20 kV substations closer to end-users, low-voltage feeder lengths are drastically shortened, reducing overall network losses by 25%–40%.

Typical deployments use compact pad-mounted or pole-top units, saving space and accelerating deployment—especially valuable in urban renewal zones and industrial parks.

2. Material Utilization and Manufacturing Cost Advantages

2.1 Material Savings Reducing Costs

- Use of high-permeability grain-oriented electrical steel (B₈ ≥ 1.89 T) reduces core cross-section by 10%, cutting material usage;

- Copper foil (vs. round wire) in LV windings improves fill factor by 12%, lowering copper loss;

- Combined optimizations reduce manufacturing costs by 18%–25% versus conventional designs.

2.2 Case Study: Industrial Park Energy Retrofit

- Cable runs from switchgear to transformers shortened by 60%, cutting civil and cabling costs by 22%;

- Despite a ¥8,000/unit higher upfront cost, the 10-year lifecycle cost (LCC) dropped from ¥186,000 to ¥98,500 per unit due to energy savings and reduced maintenance.

2.3 Economical Power Supply Models

- Dry-type transformers eliminate oil containment and fire suppression systems, reducing substation civil costs by 35%;

- Prefabricated modular substations cut construction time by 50%, ideal for fast-track projects like data centers or temporary infrastructure.

2.4 Production and Technology Synergies

Standardized modular designs support automated winding and curing processes, facilitating integration of advanced materials such as amorphous metal cores (further reducing no-load losses by 65%) or bio-based ester insulating fluids, advancing green manufacturing.

3. Applicability Analysis Across Scenarios

| Application Scenario | Core Challenges | Typical Solution | Transformation Results | Key Advantages |

|---|---|---|---|---|

| Urban Core Areas | Space constraints, strict fire codes | 2×1.6 MVA IP55 dry-type + IoT monitoring | Noise <58 dB; footprint reduced by 40% | Oil-free, fire-safe, maintenance-free, quiet |

| Solar PV Step-Up Stations | High harmonics, nighttime reactive backflow | 20 MVA oil-immersed + OLTC + AVC interface | THD reduced from 8.2% → 3.1%; curtailment ↓1.8% | Weak-grid compatibility, dynamic voltage control, inverter coordination |

| Semiconductor Fabs | Intolerant to millisecond-scale voltage sags | 4 MVA dry-type + integrated DVR | Annual interruptions: 5 → 0 | Sub-cycle response, high reliability, seismic-rated (0.6g) |

4. Recommendations for Rational Deployment

4.1 Capacity Selection Guidelines

- Core Principle: “Small capacity, dense distribution”

- Urban: ≤2.5 MVA; Industrial: ≤6.3 MVA

- Winding Configuration: Prefer Dyn11 (suppresses triplen harmonics); for renewables, consider Yyn0 with tertiary harmonic-suppression winding

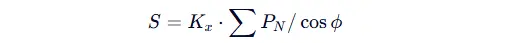

- Load Calculation:

4.2 Installation Methods

- Indoor/Underground: IP54 dry-type, natural or forced-air cooling

- Outdoor/Pole-Mounted: Fully sealed oil-immersed or compact substations, with anti-corrosion (coastal) or dust-proof (desert) treatments

- Standardized bases and plug-and-play interfaces enable rapid replacement

4.3 Hybrid Grid Coordination

- When distributed PV penetration exceeds 30%, deploy MV transformers with Automatic Voltage Control (AVC) for reactive power coordination

- For seasonal loads (e.g., agricultural irrigation), use on-load capacity-adjustable transformers (e.g., dual-rating 2/4 MVA)

4.4 Operation, Protection & Monitoring

- HV Side: Vacuum circuit breakers + IEC 61850-compliant digital relays

- LV Side: Intelligent air circuit breakers + power quality analyzers

- Lightning Protection: Gapless composite-housed ZnO surge arresters (Uc = 17 kV for 10 kV systems)

- Smart Terminal: Edge computing unit for real-time monitoring of temperature, partial discharge, and loading

4.5 Economic Considerations

- Annual energy savings: 12,000–18,000 kWh (for 2 MVA unit)

- Maintenance costs reduced by 35%

- Service life extended to 25+ years

→ 10-year LCC reduced by over 40%, with payback in ≤2.3 years

5. Future Trends and Outlook

- Material Innovations:

- Widespread adoption of amorphous metal cores will cut no-load losses by 70%–80%

- Biodegradable natural ester oils can reduce carbon footprint by 60%

- Intelligent Integration:

- Embedded IoT sensors + edge AI enable >92% accuracy in fault prediction

- Seamless integration with digital twin platforms for remote asset health assessment

- Renewable Energy Synergy:

- Support for grid-forming (GFM) control modes provides voltage/frequency stability during islanded operation

- Serve as key regulation nodes in Virtual Power Plants (VPPs)

- Standardization Evolution:

- Upcoming revisions to guidelines like Technical Principles for Distribution Network Energy Efficiency Upgrades will mandate IE4 efficiency and smart monitoring capabilities, driving industry-wide transformation.

Conclusion: The medium-voltage power transformer is evolving from a passive energy converter into an intelligent grid actuator. Through structural innovation, advanced materials, and digital integration, it will serve as the cornerstone of a high-efficiency, resilient, and zero-carbon next-generation distribution system.