330 kV–500 kV EHV Transformer: Structural Innovation, Lifecycle Economics, and Multi-Scenario Coordination Strategy

1.Structural Principles and Efficiency Advantages

1.1 Impact of Structural Differences on System Efficiency

- The autotransformer topology shares a common winding, reducing material usage by 25%–30% and lowering no-load losses by 18%–25%;

- Wound cores or optimized stepped-lap laminated cores (using B10 high-permeability silicon steel with B₈ ≥ 1.92 T) ensure continuous flux paths. Field tests on 500 kV/1000 MVA units show no-load current ≤0.08%, exceeding IE4 efficiency requirements.

1.2 Operating Principles for Suppressing Additional Losses

- Combined electrostatic shields and magnetic shunts effectively suppress stray losses caused by 3rd/5th harmonics from HVDC converters or wind farms;

- Segmented foil-type tap windings minimize eddy currents and enhance OLTC switching reliability;

- Due to high voltage and low current, I²R transmission losses at the same power level are only ~40% of those in 220 kV systems.

1.3 System-Level Power Delivery Optimizes Overall Efficiency

Typical projects use HGIS-integrated layouts or compact outdoor substations, saving 30% land area—ideal for ecologically sensitive or mountainous regions.

2. Material Utilization and Lifecycle Cost Advantages

2.1 High-Performance Materials Reduce Manufacturing and Operational Costs

- B10 high-permeability silicon steel reduces core cross-section by 12%, cutting material costs by 15%;

- High-purity oxygen-free copper (OFC, ≥99.99%) in HV windings lowers load losses by 8%;

- Integrated optimization has reduced per-MVA manufacturing costs by 22% over the past decade while enhancing reliability.

2.2 Case Study: Northwest Renewable Export Corridor Upgrade

- One transmission corridor was eliminated, reducing land acquisition and civil works costs by ¥120 million;

- Annual energy savings reached 28 GWh; 10-year LCC dropped from ¥360 million to ¥210 million (including O&M, losses, and outage costs);

- Despite a ¥25 million higher upfront cost per unit, payback period was just 2.1 years.

2.3 Economical System Deployment Models

- Autotransformers eliminate the need for a separate tertiary winding, saving space in tanks and cooling systems, reducing substation footprint by 25%;

- Modular transport and on-site assembly support deployment in remote areas (e.g., plateaus, islands), shortening construction time by 40%.

2.4 Manufacturing and Technology Synergy

- Optional amorphous metal cores (pilot projects show 65% further reduction in no-load loss);

- Natural ester insulating oil (K-class fire rating, >98% biodegradability) meets green grid certification standards.

3. Multi-Scenario Applicability Analysis

| Application Scenario | Core Challenge | Typical Solution | Performance Outcome | Key Advantage |

|---|---|---|---|---|

| National Grid Hub | Excessive short-circuit current, insufficient N-1 margin | 1500 MVA 500 kV autotransformer + high-impedance design | Short-circuit current limited from 63 kA → 50 kA | High fault withstand, strong system support |

| Cross-Border Interconnection (e.g., China–Laos) | Mismatched voltage standards, frequency instability | 330 kV three-winding transformer + OLTC ±10% | Voltage compliance improved from 92% → 99.6% | Multi-voltage adaptability, dynamic regulation |

| Large Offshore Wind Export | Weak-grid connection, resonance risk | 1000 MVA oil-immersed transformer + broadband damping winding + AVC interface | Subsynchronous oscillation (SSO) suppression >90% | Anti-resonance, grid-forming capability, remote control |

4. Rational Application Guidelines

4.1 Capacity and Selection Principles

- Backbone nodes: ≥1000 MVA (500 kV class); regional interties: 500–800 MVA (330 kV class);

- Winding configuration: Prefer YNa0d11 (provides zero-sequence path); cross-border projects may use Yy0 + tertiary winding;

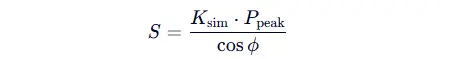

- Capacity verification formula:

4.2 Installation and Environmental Adaptation

- Outdoor installation: Fully sealed tank + C5-M anti-corrosion coating + IP54 protection;

- Seismic zones (e.g., Indonesia, Philippines): Certified to 0.3g horizontal acceleration (IEC 60068-3-3);

- High-temperature/humidity regions: ODAF cooling with 55°C temperature rise design ensures full-load operation without derating.

4.3 Coordination with Renewable Integration

- When renewable penetration exceeds 40%, integrate AVC (Automatic Voltage Control) interfaces for coordination with dispatch centers;

- Support STATCOM/SVC co-control to provide dynamic reactive power (±300 Mvar), maintaining PCC voltage fluctuation within ±3%.

4.4 Intelligent Protection and Maintenance

- HV side: SF₆ circuit breaker + digital differential protection (<20 ms trip time);

- On-unit monitoring: Fiber-optic DTS (hotspot), UHF partial discharge, DGA (dissolved gas analysis);

- Smart terminal: Edge computing unit compliant with IEC 61850-7-420, enabling fault prediction accuracy >90%.

4.5 Lifecycle Economic Evaluation

- Annual energy savings of 1.5–2.5 GWh (for 1000 MVA units);

- 60% reduction in outage duration;

- Design life extended to 30 years;

Resulting in >35% lower 10-year LCC and a payback period ≤2.5 years.

5. Future Development Trends

- Material Innovation:

- Widespread adoption of amorphous metal cores could reduce no-load losses by 70%–80%;

- Natural ester oil will cut carbon footprint by 60%, supporting national “dual carbon” goals.

- Deep Intelligence Integration:

- Embedded IoT sensors + edge AI models enable remaining-life prediction with <8% error;

- Digital twin platforms support remote “health checkups” and predictive maintenance.

- Synergy with Next-Generation Power Systems:

- Support grid-forming control, providing voltage/frequency references during islanding or black-start;

- Serve as critical physical nodes in Virtual Power Plants (VPPs) and cross-regional flexibility resource pools.

- Standards and Policy Drivers:

- The upcoming “Minimum Energy Performance Standards for EHV Transformers” will mandate IE4 efficiency and real-time monitoring;

- The Belt and Road Green Infrastructure Guidelines will prioritize low-loss, intelligent, and locally supported products.