330 kV–500 kV EHV power transformer: Structural Innovation, System-Level Economics, and Multi-Scenario Coordination Strategies

1.Structural Principles and Efficiency Advantages

1.1 Structural Differences Affecting Efficiency

- Advanced transposed conductor winding techniques (e.g., continuous + helical hybrid configurations) effectively suppress eddy currents and circulating losses.

- Field measurements show that modern 500 kV autotransformers achieve 8%–12% lower load losses and maintain partial discharge levels below 100 pC under rated conditions—meeting stringent requirements for ultra-high-voltage projects—compared to traditional 220 kV three-winding transformers of equivalent power transfer capacity.

1.2 Operating Principles Minimizing System Losses

- The autotransformer connection provides a lower short-circuit impedance (typically 8%–12% vs. 14%–18% in conventional transformers), reducing system voltage drop and reactive power demand.

- In long-distance transmission, this lowers line current by 15%–25%, resulting in an overall network loss reduction exceeding 20%.

- It eliminates the need for cascaded lower-voltage transformers, thereby avoiding cumulative losses and compounded failure risks.

1.3 Transmission Architecture Optimizing Grid Efficiency

Typical projects adopt compact HGIS (Hybrid Gas-Insulated Switchgear) layouts, reducing substation footprint by 40% and accelerating construction—particularly advantageous in deserts, plateaus, and other challenging terrains.

2. Material Utilization and Manufacturing Cost Advantages

2.1 Advanced Materials Enhancing Cost-Effectiveness

- Use of Grade B10 high-permeability grain-oriented electrical steel (magnetic flux density ≥ 2.03 T) reduces core volume by 10% and no-load losses by 15%.

- Continuously transposed cable (CTC) and self-bonding enameled wire improve winding mechanical strength and thermal stability.

- Although unit costs are high (approximately ¥30–50 million RMB per 500 kV transformer), the cost per kVA is 18%–22% lower than 220 kV solutions due to higher unit capacity and fewer required units.

2.2 Case Study: Northwest Renewable Energy Export Corridor

- High-voltage equipment count reduced by 50%, cutting GIS/HGIS investment by 30%.

- Annual network losses decreased by ~120 GWh, equivalent to 96,000 tons of CO₂ reduction.

- Despite a ¥120 million higher upfront cost, the 10-year lifecycle cost (LCC) was reduced by ¥380 million, factoring in energy savings, O&M, and land use.

2.3 System-Level Cost Optimization

- Fewer substations simplify grid dispatch logic and communication infrastructure.

- Dynamic rating capabilities—enabled by real-time hotspot temperature monitoring—boost asset utilization by 10%–15%.

2.4 Manufacturing and Supply Chain Strengths

| Application Scenario | Core Requirements | Typical Solution | Implementation Results | Key Advantages |

|---|---|---|---|---|

| Cross-Regional Renewable Export | High capacity, low loss, high reliability | 500 kV / 1,200 MVA autotransformer + ODAF cooling | Transmission efficiency: 98.7%; annual utilization >5,000 hrs | Enables GW-scale wind/solar integration |

| Inter-Regional Grid Interconnection | Flexible power flow control, N-1 security | 330 kV intertie transformer + STATCOM coordination | Power flow response <100 ms; transient stability ↑30% | Enhances multi-province power sharing |

| Large Industrial Complex Supply | High power quality, short-circuit resilience | 500/35 kV direct-step-down transformer (no intermediate voltage) | Voltage fluctuation <±1%; withstands 63 kA/3s | Simplifies topology, improves reliability |

4. Recommendations for Rational Deployment

4.1 Capacity and Configuration Guidelines

- Core Principle: “Large capacity, fewer sites, strong interconnection”

- Renewable export hubs: ≥1,000 MVA; regional hubs: 500–800 MVA

- Winding Connection: Prefer YNa0d11 (autotransformer with delta tertiary winding) to provide zero-sequence path and suppress harmonics

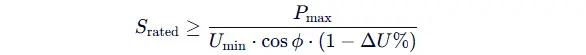

- Capacity Sizing Formula:

4.2 Installation and Layout Methods

- Indoor/Underground: Reserved for urban cores; requires ODWF cooling and SF₆ leak detection

- Outdoor Open-Type: Standard approach, paired with acoustic barriers (noise ≤65 dB) and firewalls

- Promote modular transport and on-site assembly to overcome weight restrictions in mountainous or bridge-limited areas

4.3 Coordination with the New Power System

- When connected renewable penetration exceeds 40%, integrate broadband impedance-matching windings to suppress subsynchronous oscillation (SSO)

- In regions with high seasonal output variability, adopt on-load tap changers integrated with dynamic VAR compensation

4.4 Operation, Protection, and Monitoring

- HV Side: SF₆ circuit breakers + digital differential relays (IEC 61850-9-2LE compliant)

- Transformer Monitoring: Fiber-optic DTS (distributed temperature sensing), UHF partial discharge detection, online DGA (dissolved gas analysis)

- Lightning Protection: 500 kV ZnO surge arresters (residual voltage ≤1,050 kV)

- Fire Suppression: Dual-system design combining oil drainage & nitrogen injection with water spray

4.5 Economic Considerations

- Annual loss reduction of 8,000–15,000 MWh (for 1,200 MVA units)

- Elimination of intermediate voltage substations (saving land and O&M)

- Service life of 30–40 years

→ Total lifecycle cost (LCC) is over 35% lower than multi-stage step-down alternatives, offering significant societal and economic benefits.

5. Future Trends and Outlook

- Material and Process Innovation:

- Nanocrystalline alloy cores (in prototype phase) could further reduce no-load losses by ~50%

- Eco-friendly insulating gases (e.g., g³, Clean Air) are gradually replacing SF₆, cutting global warming potential (GWP) by 99%

- Deep Intelligence Integration:

- Embedded digital twin models enable lifetime prediction, fault simulation, and remote diagnostics

- Seamless coordination with grid dispatch systems for participation in AGC (Automatic Generation Control) and primary frequency regulation

- Enabling the New Power System:

- Serve as grid-forming (GFM) interfaces, providing inertia and short-circuit capacity in weak AC grids

- Collaborate with VSC-HVDC converter stations to build hybrid AC/DC backbone networks

- Standards Evolution:

- Upcoming revisions to guidelines such as Technical Principles for EHV Transformer Design and Grid Integration Standards for Renewable Energy Bases will mandate broadband oscillation damping and ultra-fast protection response (<20 ms), driving industry transformation.

Conclusion: The 330–500 kV EHV power transformer has evolved beyond a mere energy converter—it is now the “valve of the national power artery.” Through relentless innovation and system-level synergy, it will play an irreplaceable role in building a secure, efficient, green, and intelligent modern energy system.