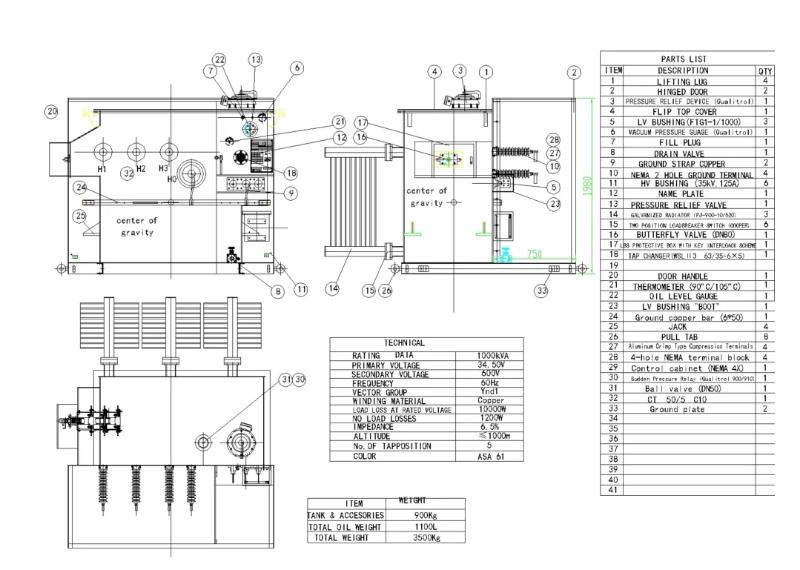

35kV 3 Phase Oil-immersed Grounding transformers

| Brand | Vziman |

| Model NO. | 35kV 3 Phase Oil-immersed Grounding transformers |

| Rated voltage | 35kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 500kVA |

| Series | JDS |

Yes, it can be flexibly matched with both systems. When used in a resonant grounding system, it coordinates with arc suppression coils to extinguish ground fault arcs; when used in a resistance grounding system, it works with neutral grounding resistors to limit fault current, meeting the grounding protection requirements of different 35kV power grids.

Q:How to confirm that the 35kV Oil-immersed Grounding Transformer matches the ambient conditions of the installation site?

A:Focus on three key environmental indicators: first, the ambient temperature range, generally requiring adaptation to -40℃ to +40℃; second, the altitude, with most products suitable for areas below 1000m (derating is required for high-altitude areas); third, the pollution level, selecting corresponding anti-pollution coating tanks for coastal, chemical or dusty areas.

Q:Can the tank of 35kV Oil-immersed Grounding Transformers be customized for special scenarios?

A:Yes, customization is supported. For coastal areas with high salt spray, anti-corrosion alloy tanks or heavy-duty anti-rust coating tanks can be customized; for mining areas with frequent vibrations, shock-absorbing base structures can be added; for areas with strict noise requirements, low-noise tank designs with sound insulation layers are available.

The comprehensive protection configuration of the Kete earthing transformer serves as the “first line of defense”, effectively preventing faults that the transformer may encounter during operation, such as short circuits (e.g., inter-turn short circuits of windings, short circuits to ground), overloading, and excessive oil temperature.

①Electrical Protection

·Current quick-break protection: Designed to handle severe short-circuit faults.

·Overcurrent protection: Addresses general short-circuit faults or overloading issues.

·Zero-sequence current protection: Targets faults in the grounding system.

When triggered, these protection mechanisms can quickly initiate tripping or issue alarms.

②Non-Electrical Protection

·Oil temperature protection: Triggers an alarm or tripping when the top-layer oil temperature exceeds the safe threshold.

·Oil level protection: Issues an alarm when the oil level is too low or too high, preventing insufficient insulating oil or tank deformation.

·Gas protection (Buchholz protection): Activates an alarm or tripping when gas is generated inside the tank, responding to minor internal faults or severe short circuits.

③Accuracy of Protection Settings

Protection settings are calibrated based on transformer parameters (e.g., rated current, short-circuit current) and system requirements. This calibration prevents “maloperation” (tripping during normal operation) or “failure to operate” (no response when a fault occurs).

The choice between ONAN (Oil Natural Circulation and Air Natural Cooling) and ONAF (Oil Natural Circulation and Air Forced Cooling) cooling methods for Kete oil-immersed grounding transformers is corely based on the matching between the transformer’s heat dissipation requirements and actual heat dissipation conditions. Specifically, it can be comprehensively judged from the following 5 key dimensions:

①Transformer Rated Capacity and Heat Generation from Losses

This is the most fundamental basis. The heat generated by a transformer mainly comes from copper losses (load losses) and iron losses (no-load losses). The larger the capacity, the higher the losses and the stronger the heat dissipation demand:

·Small-capacity transformers (low loss):

When the rated capacity is small (e.g., ≤500kVA for 10kV class, ≤1000kVA for 35kV class), the heat generated by losses is small. Heat can be dissipated through the natural convection of transformer oil (hot oil rises, cold oil falls) and the natural convection between the casing/radiator and air, without the need for additional cooling equipment. Therefore, ONAN is preferred.

·Medium and large-capacity transformers (high loss):

When the capacity exceeds the above range (e.g., ≥800kVA for 10kV class, ≥1600kVA for 35kV class), losses increase significantly, and the natural heat dissipation rate cannot match the heat generation. This may cause the oil temperature to exceed national standard limits (usually top oil temperature rise ≤55K or 60K). In such cases, fans must be used to force air flow and accelerate heat dissipation, so ONAF is chosen.

②Operating Load Characteristics

The actual load rate and operation mode of the transformer directly affect heat dissipation requirements:

·Low load rate or intermittent operation:

If the transformer operates at light load for a long time (load rate < 50%) or only runs during short-term peak periods (e.g., rural distribution transformers), even if its capacity is slightly larger, the actual heat generation is low. The natural heat dissipation capacity of ONAN can meet the demand, and there is no need to waste energy on fans. Thus, ONAN is selected.

·High load rate or continuous full-load operation:

For transformers in industrial parks, urban core distribution networks, and other equipment that operate at full load for a long time or have large load fluctuations (needing to cope with short-term overload), heat generation remains high. ONAN cannot meet the heat dissipation requirements, so ONAF’s forced air cooling via fans is necessary. Even during overload, fans can enhance heat dissipation capacity (usually supporting 10%-20% short-term overload). Hence, ONAF is chosen.

③Installation Environment and Heat Dissipation Conditions

Environmental factors directly affect the efficiency of natural heat dissipation, and cooling methods need to be adjusted according to scenarios:

·Well-ventilated and low-temperature environments:

If the transformer is installed in an open outdoor area, high-altitude regions (low air density but good ventilation), or cold areas, the efficiency of natural convection heat dissipation is high. Even if the capacity is close to the critical value, ONAN can be prioritized.

·Poorly ventilated and high-temperature environments:

④Cost and Maintenance Requirements

maintenance costs almost zero. It is suitable for scenarios sensitive to cost and with limited maintenance resources (e.g., rural power grids, small user transformers).

Kete oil-immersed grounding transformers mainly adopt two common cooling methods: ONAN and ONAF.

①Scope of Application of ONAN

·Transformers with small capacity

Typical applicable capacity: Usually used for transformers of 10kV class with 500kVA and below, and 35kV class with 1000kVA and below.

Reason: Small-capacity transformers have low losses (small heat generation), and natural heat dissipation can meet the temperature rise requirements, with a simple structure and low cost.

·Scenarios with loose installation environment

Suitable for outdoor open spaces, well-ventilated indoor distribution rooms, or areas with low ambient temperatures.

If installed in enclosed spaces (such as basements), additional evaluation of heat dissipation conditions is required, and the cooling method may need to be upgraded.

·Transformers with low load rate or intermittent operation

For transformers that are in a light load state for a long time (load rate < 50%), the heat dissipation capacity of ONAN is sufficient, without wasting energy consumption from forced cooling.

②Scope of Application of ONAF

·Medium and large capacity transformers

Typical applicable capacity: 10kV class with 800kVA and above, 35kV class with 1600kVA and above for small and medium-sized transformers.

Reason: Medium and large-capacity transformers have high losses (large copper loss and iron loss), and natural heat dissipation cannot meet the temperature rise limit, so fans are needed to assist in enhancing heat dissipation.

·Transformers with high load rate or continuous operation

Suitable for scenarios with long-term full-load operation or large load fluctuations (needing to cope with short-term overload), such as main transformers in industrial plants and hub transformers in urban distribution networks.

·Environments with limited heat dissipation conditions

If the transformer is installed in a poorly ventilated indoor environment or in areas with high ambient temperatures (such as tropical regions), ONAF can make up for the deficiency of natural heat dissipation through forced air cooling, avoiding excessive oil temperature that affects service life.