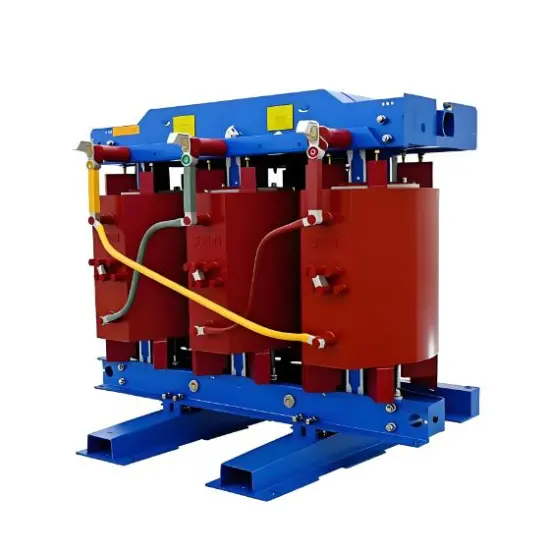

Three Phase HV Dry-Type Distribution Transformer Manufacturer-11kV 27kV 33kV 40.5kV

| Brand | Vziman |

| Model NO. | Three Phase HV Dry-Type Distribution Transformer Manufacturer-11kV 27kV 33kV 40.5kV |

| Rated voltage | 40.5kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 315kVA |

| Series | SCB |

- Superior Fire Safety:Oil-free design eliminates leakage and fire risks, perfectly suited for enclosed spaces like data centers and high-rises.

- High Insulation Performance:Epoxy resin casting/VPI process ensures strong resistance to moisture, dust, and chemical corrosion, adapting to harsh operating environments.

- Wide Voltage Compatibility:Covers 11kV/27kV/33kV/40.5kV voltage grades, matching diverse power distribution network requirements with flexible tap range adjustment.

- Low Loss & Energy Saving:Adopts high-quality silicon steel cores and oxygen-free copper windings to minimize no-load and load losses, reducing long-term operation costs.

- Easy Maintenance:No oil sampling or replacement required; equipped with intelligent temperature monitoring systems for real-time operation status tracking.

- Compliant with Global Standards:Manufactured in accordance with IEC 60076 and GB 1094 standards, with optional CE certification for global market access.

HV Dry-Type Distribution Transformer Manufacturer Technical Parameters

|

Class F Insulation SCB10-315~2500/10

|

||||||

|

Rated High Voltage:6kV 6.3kV 6.6kV 10.5kV 11kV 40.5kV 33kV 27kV 10kV

|

||||||

|

Rated Low Voltage:0.4kV

|

||||||

|

Connection Group: Dyn11or Yyn0

|

||||||

|

Insulation Level: Ll 75 AC 35 / Ll AC 3; Tap Range:±2*2.5%

|

||||||

|

Model

|

UK%

|

P0(W)

|

Pk(120℃)(W)

|

I0%

|

LPA(AN)dB

|

Gauge m x n (mm)

|

|

SCB10-315/10

|

4

|

880

|

3470

|

1.0

|

55

|

660 x 660

|

|

SCB10-400/10

|

4

|

980

|

3990

|

1.0

|

55

|

660 x 660

|

|

SCB10-500/10

|

4

|

1160

|

4880

|

1.0

|

57

|

660 x 660

|

|

SCB10-630/10

|

4

|

1340

|

5880

|

0.85

|

57

|

820 x 820

|

|

SCB10-630/10

|

6

|

1300

|

5960

|

0.85

|

57

|

820 x 820

|

|

SCB10-800/10

|

6

|

1520

|

6960

|

0.85

|

58

|

820 x 820

|

|

SCB10-1000/10

|

6

|

1770

|

8130

|

0.85

|

58

|

820 x 820

|

|

SCB10-1250/10

|

6

|

2090

|

9690

|

0.85

|

60

|

820 x 820

|

|

SCB10-1600/10

|

6

|

2450

|

11700

|

0.85

|

60

|

820 x 820

|

|

SCB10-2000/10

|

6

|

3050

|

14400

|

0.70

|

62

|

820 x 820

|

|

SCB10-2500/10

|

6

|

3600

|

17100

|

0.70

|

62

|

820 x 820

|

Utilizing epoxy resin vacuum casting technology, they offer fire/explosion-proof safety, maintenance-free operation, and IP54 protection—ideal for indoor and harsh environments (mines, chemical plants, renewable energy stations).

Q: What technologies are adopted to ensure the excellent insulation and fire resistance of HV dry-type distribution transformer?

A:The adoption of advanced epoxy resin casting or VPI vacuum pressure impregnation technology ensures superior insulation performance. Meanwhile, the oil-free design fundamentally eliminates the risks of oil leakage and fire, and the insulation structure formed by these processes also enhances fire resistance, making the transformers suitable for high-fire-risk scenarios.

Q:What voltage grades do HV dry-type distribution transformer cover, and how to adapt to diverse power grid requirements?

A:They cover 11kV, 27kV, 33kV and 40.5kV voltage grades, which can match the needs of different power distribution networks. In addition, the transformers are designed with flexible tap range adjustment, enabling precise voltage regulation to adapt to the operating characteristics of various power grids.

Q:What design helps HV dry-type distribution transformer achieve low loss and energy-saving effects?

A:The adoption of high-quality silicon steel cores and oxygen-free copper windings is the key to low loss. These high-performance materials effectively minimize both no-load losses and load losses during operation, thereby reducing long-term energy consumption and operational costs for users.

Q:Why are HV dry-type distribution transformer considered easy to maintain, and what auxiliary functions support operation monitoring?

A:The oil-free design eliminates the need for regular oil sampling and replacement, greatly reducing maintenance workload. Besides, each transformer is equipped with an intelligent temperature monitoring system, which can track the real-time operation status and provide timely reminders for potential faults.